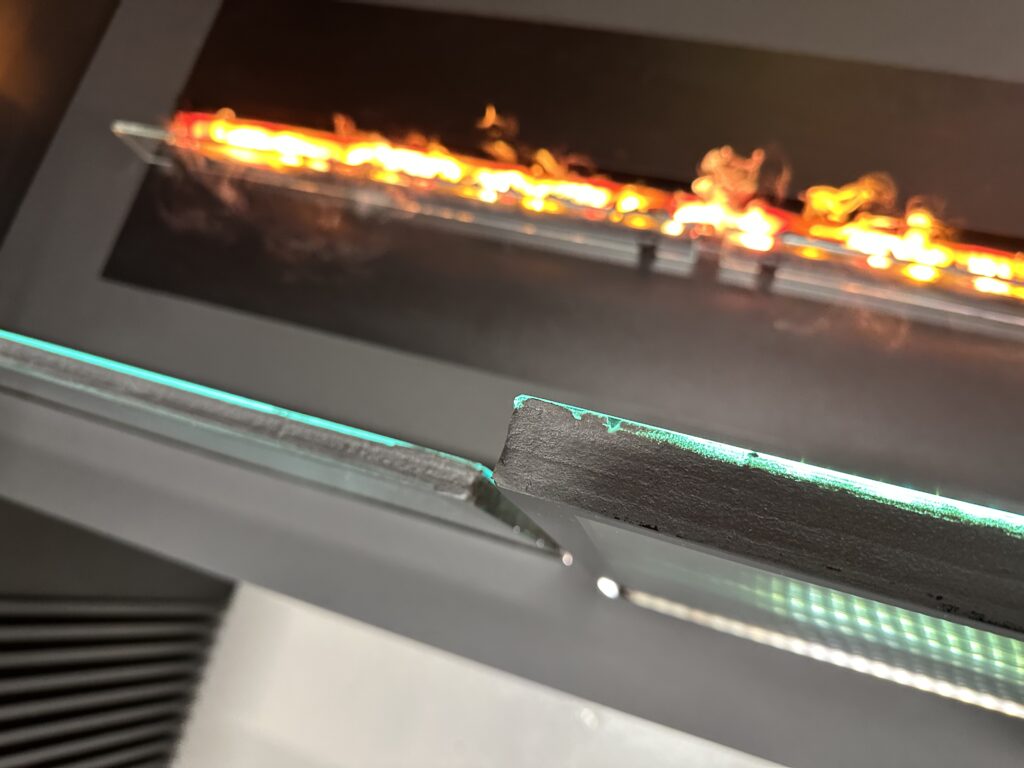

Fire Rated Glazing Systems

Advanced Glass: Certified Fire Rated Glazing Systems

At Advanced Glass, we supply and install fire-rated glazing systems that combine performance, aesthetics, and compliance for high-risk and high-specification buildings. Our systems are fully tested and certified to meet the latest fire safety standards and are ideal for applications where compartmentation and life safety are critical.

We offer solutions in both aluminium and steel framed systems, each with distinct advantages depending on project requirements, performance ratings, and aesthetic goals.

Integrity & Insulation – Understanding Fire Glass Classifications

There are two primary classifications for fire-rated glazing, and the right choice depends on the building’s fire strategy:

- Integrity Only (E-rated): Prevents the passage of flames and hot gases but allows radiant heat to pass through. Typically used in areas where radiant heat is less of a concern.

- Integrity and Insulation (EI-rated): Provides the same flame and smoke resistance, but also limits heat transfer through the glazing for the rated period. This is often a requirement in escape routes, communal lobbies, or compartment lines in high-rise residential and public buildings.

These fire-rated systems typically use advanced laminated glazing with intumescent interlayers that react to heat, expanding to form a thermally insulating barrier during a fire.

Certified Performance Ratings

We provide systems that are tested to meet performance ratings of:

- 30 minutes (EI30 or E30)

- 60 minutes (EI60 or E60)

- 90 minutes (EI90 or E90)

- 120 minutes (EI120 or E120)

All systems are third-party tested and compliant with BS EN 1364 and BS EN 1634 fire resistance testing standards.

Aluminium vs Steel Framing

- Aluminium fire-rated systems offer lightweight and sleek profiles, ideal for modern architectural design while still offering robust performance up to EI120.

- Steel fire-rated systems provide even higher structural strength and are often selected for larger spans, heritage or industrial-style designs, or where higher integrity is needed within the same footprint.

Typical Applications

- Internal glazed partitions and screens

- Fire-rated curtain walling

- Lobby and corridor glazing

- Vision panels in fire doors

- Smoke lobbies and escape routes

- Facade openings within compartment walls

Complete Envelope Integration

As a façade contractor with in-house expertise, we ensure fire-rated glazing integrates seamlessly with surrounding cladding, curtain walling, windows, and fire stopping. This ensures that compartment lines are maintained without compromise — reducing coordination issues and removing grey areas between trades.

Quality Assurance

All fire-rated glazing installations follow a documented QA process, with photographic evidence of each element. This supports the Golden Thread of Information and helps clients meet Gateway 2 and Gateway 3 sign-off requirements under the Building Safety Act.

Let’s Talk Fire Performance

If your project involves complex fire strategy requirements or demands performance-led façade solutions, Advanced Glass can help. We work closely with system suppliers and fire engineers to ensure compliance, reliability, and peace of mind.

Contact our team today to discuss specifications or request a fire-rated glazing proposal for your next project.

Frequently Asked Questions

Aluminium windows offer durability, low maintenance, excellent thermal efficiency, and modern aesthetics, making them ideal for commercial applications.

Yes, modern aluminium windows feature thermal break technology to improve insulation, achieving low U-values meeting Part L building regulations and often exceeding it.

Options include double or triple glazing, solar control glass, acoustic glass, laminated safety glass, and enhanced security glass, depending on performance needs.

Yes, commercial aluminium windows can be PAS 24 certified and meet Secured by Design standards with multi-point locking systems with reinforced frames.

When properly maintained, aluminium windows can last 30 – 40 years, due to their corrosion resistance and high-quality powder-coated finishes.

Yes, they are available in a wide range of RAL colours, anodised finishes, and different configurations, including casement, tilt-and-turn, and sliding options.

Aluminium windows are designed to withstand extreme weather conditions, with high wind load resistance and water-tightness ratings to ensure long-term performance.

Minimal maintenance is needed – just the occasional cleaning and lubrication of moving parts is required to help ensure smooth operation and longevity.

Yes, aluminium is up to 100% recyclable, and many modern aluminium window systems use recycled materials, supporting sustainable building practices.

Lead times vary depending on customisation and project size, but standard windows typically take 12 – 16 weeks for design, manufacturing and delivery.

Would You Like To Discuss A Particular Project?

If you’re looking for a specialist curtain walling, facade, or cladding contractor to assist you with your upcoming project, ensuring on-time delivery and a smooth process from start to finish, our expert team are on hand and ready to assist you.