Proteus Rainscreen Cladding System

Proteus Rainscreen Cladding Systems

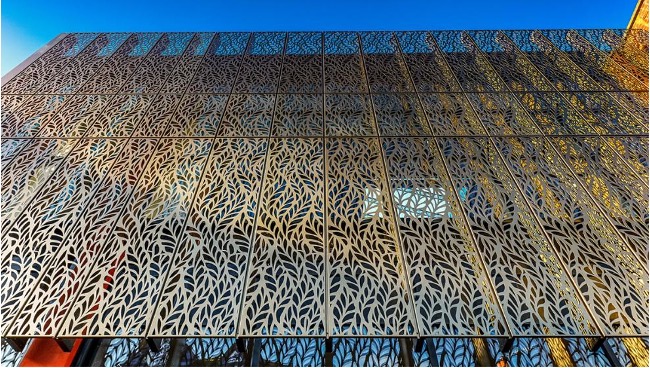

Proteus SR – Fire-Rated Metal Rainscreen Cladding

Proteus SR is an A1 or A2-rated metal rainscreen cladding system, offers outstanding performance and design flexibility Proteus SR is a sleek, modern solution for new builds, refurbishments, and recladding projects.

Fire Performance

Proteus SR has been tested in accordance with EN 13501, achieving a fire classification of A1 or A2-s1, d0, depending on the specified face material and finish. All fire breaks and insulation must be installed by a competent contractor in line with the project’s fire strategy and regulatory requirements.

CWCT Testing

Proteus SR has successfully undergone extensive testing in line with CWCT standards for ventilated rainscreen cladding systems. This includes water tightness testing under dynamic pressure, wind resistance assessment for both serviceability and safety, and durability testing, demonstrating resistance to both soft and hard body impacts.

System Features

The Proteus SR system is rated A1 or A2-s1, d0 for fire performance. It is available in aluminium, stainless steel, or weathering steel face materials. Panels are secret-fixed using a precision-engineered hook-on system. Joints are 20mm recessed and aligned with the panel face, while reveals use continuous closer panels for depths up to 175mm. A wide range of finishes is available, including RAL powder-coated, anodised, pre-coated, and weathered options.

Installation & Design Flexibility

Proteus SR panels are available in thicknesses from 1.5mm to 5.0mm and can be installed vertically, horizontally, or in mixed orientations. The hook-on fixing system allows for excellent on-site adjustability, ensuring precise alignment during installation.

Carrier rails are connected to project-specific brackets, designed to achieve the required cavity depth and fitted with thermal isolator pads. This configuration ensures compatibility with all typical substructures, such as blockwork, concrete, steel framing systems (SFS), timber frame, and structural insulated panels (SIPs). Horizontal rails can also be integrated where required by the supporting frame design.

Each panel is supported by a precision-engineered system of aluminium carriers and ancillary components, which are compatible with all standard wall constructions, including concrete, blockwork, steel framing systems (SFS), and timber frames.

The honeycomb structure of Proteus HR is naturally optimised to provide excellent compression and shear resistance. As a result, the system minimises the load imposed on the building’s primary structure and reduces overall material consumption when compared to conventional solid metal rainscreen panels.

Standard panel thicknesses range from 15mm to 25mm, with custom options available to suit specific design and structural requirements. Panels can be manufactured in sizes up to 1,500mm by 4,000mm, subject to material and wind load considerations.

Depending on the panel configuration, overall weight typically falls between 6 and 9 kilograms per square metre.

Proteus SP – Insulated Spandrel Panel System

Proteus SP is a high-performance insulated spandrel panel system designed to integrate seamlessly into curtain walling or window systems. It is available with a choice of facing materials, including aluminium, steel, porcelain ceramic, and back painted glass, offering excellent design flexibility to meet the aesthetic and technical requirements of modern façades.

This system is manufactured using a non-combustible mineral fibre insulation core, which is structurally bonded to the external face. The rear skin is typically formed from steel or aluminium, while the front face can be finished in a wide range of materials and colours to suit the overall façade design. Panels are inserted into prepared glazing openings and secured on all four edges within the glazing system, delivering a neat and robust installation.

The Proteus SP system has been tested to achieve fire classifications in accordance with EN 13501. All standard configurations—whether using PPC aluminium between 0.9mm and 5.0mm, PPC steel from 0.7mm to 3.0mm, 4.0mm back painted toughened glass, or 3.0mm porcelain ceramic—achieve an A2-s1, d0 rating. Where a project specifies materials or finishes not currently covered by existing tests, project-specific classification to EN 13501 can be undertaken.

Thermal performance is delivered through the mineral fibre core, which has a linear thermal conductivity of 0.038 WmK. The system is highly adaptable, with insulation depths ranging from 20mm to 200mm, allowing the overall panel depth to vary from 21.4mm to 210mm. This flexibility enables Proteus SP to meet a wide range of U-value requirements, with centre pane values as low as 0.19 W/m²K achievable through the appropriate configuration.

Acoustic performance is also a key consideration in the design of Proteus SP panels. By adjusting the thickness and composition of the inner and outer metal skins, a variety of sound reduction values can be achieved. Increased panel mass contributes to higher dB ratings, and the system can be tailored to meet the specific acoustic needs of each project.

The technical team at Proteus can provide guidance on the most effective panel build-up for achieving targeted sound insulation values.

Every panel is manufactured to bespoke sizes and assembled under factory-controlled conditions for precision and quality. Finishes include standard RAL powder coatings, specialist colours, and a selection of porcelain ceramic materials. The composite construction can be broken down for full recyclability, supporting sustainability objectives and circular design principles.

Spandrel panels serve both a functional and aesthetic role in façade design. They are commonly used to conceal floor slabs, ceiling voids, and building services, while maintaining visual consistency across the glazed areas of a building. With large-format options offering exceptional flatness, Proteus SP panels provide architects with a versatile and high-performing solution for integrated façade design.

Proteus SP – Engineered Panel System

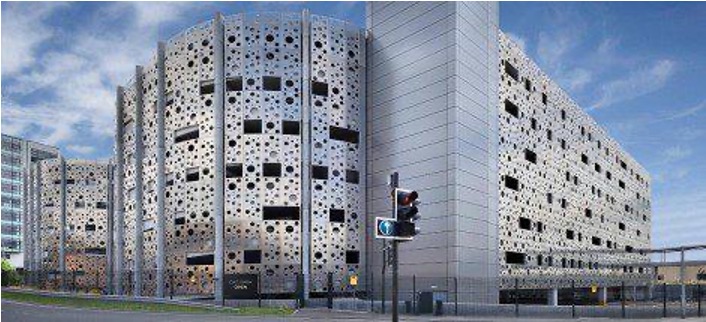

Proteus SC is a versatile engineered cladding system offering solid, perforated, or expanded mesh panel formats. Manufactured from sheet metal ranging from 1mm to 5mm in thickness, the system accommodates a broad selection of metals, including aluminium, copper, stainless steel, zinc, and porcelain ceramic. Each material choice influences panel dimensions and structural design, with certain materials imposing limitations on width and thickness. However, Proteus SC is engineered to navigate these constraints, ensuring optimal design solutions tailored to project specifications.

The system’s design incorporates considerations for live loadings, aesthetic preferences, and functional requirements such as airflow. The perforation pattern and mesh size are meticulously planned to balance visual appeal with performance criteria. Proteus SC panels are supported by a bespoke aluminium carrier system, facilitating installation on various wall constructions. In specific applications, these carriers are designed to span between structural floors, eliminating the need for secondary structural elements.

For internal applications, Proteus SC panels can be enhanced with an acoustic insulation layer encapsulated within the panel. Additionally, contrasting fabric inserts can be incorporated into perforated panels to achieve desired aesthetic effects.

The Proteus SC system is suitable for a wide array of applications, including car parks, stair towers, window screens, plant screens, balconies and balustrading, acoustic panels, sun screening, external wall coverings, and internal wall coverings. Its adaptability makes it an ideal choice for both functional and decorative cladding solutions in various architectural settings.

Proteus AR Louvre System

The Proteus AR system is an engineered aluminium louvre solution designed for seamless integration into modern building facades. Utilising a unique plastic clip system, the louvres are securely fixed to the Proteus carrier framework, facilitating quick and efficient installation.

Manufactured from extruded aluminium, the system ensures structural integrity and precision, offering flexibility to accommodate various architectural requirements.

The range includes framed modular louvres, frameless continuous louvres, louvre doors, profiled louvres, and brise soleil systems. Framed modular louvres come pre-assembled with louvre blades encased within frame surrounds, allowing for immediate installation on-site. Integrated edge details are designed to interface with a variety of facade systems. Frameless continuous louvres are available in screening, standard weather, and high-performance weather configurations. These louvres are fabricated into kits for on-site assembly and include jamb, head, and sill flashings for integration with facade systems or fitting within building openings.

Louvre doors are factory-built and can be flush integrated within continuous louvres or offered with a frame for incorporation into a facade or opening. These doors come equipped with all necessary ironmongery and can be customised to specification, including options for hinges, pivots, cylinder locks, fob access, keypad access, panic bars, and deadbolts. Profiled louvres provide a streamlined option for specific facade integrations, offering an economical solution.

Brise soleil systems are designed to assist in meeting current building regulations by reducing unwanted solar heat gain, thereby decreasing the need for air conditioning while maintaining desirable daylight levels. The range comprises extruded aluminium fins, support arms, and fixing brackets, with designs and engineering tailored to suit individual project requirements.

Optional accessories for the Proteus AR system include bird guards, insect mesh, single-skin blanking plates, and insulated blanking plates, allowing for further customisation to meet specific project needs.

Frequently Asked Questions

Rainscreen cladding is an external façade system designed to protect buildings from weather, improve thermal efficiency, and enhance aesthetic appeal. It creates a ventilated cavity that helps manage moisture and insulation.

It consists of an outer cladding layer that deflects rainwater and an inner wall with insulation. The ventilated cavity allows air to circulate, helping to prevent moisture buildup and improve energy efficiency.

Common materials include aluminium, zinc, stainless steel, high-pressure laminate (HPL), fibre cement, stone, glass, and terracotta, offering various design and performance benefits.

Fire performance depends on the material used. Non-combustible options, such as A1 or A2-rated metal and mineral-based cladding, comply with UK fire safety regulations (Approved Document B).

Key benefits include weather protection, thermal efficiency, improved acoustics, reduced maintenance, and a modern architectural finish.

Yes, rainscreen cladding works with high-performance insulation to improve U-values, and meet Part L building regulations.

Depending on material and maintenance, rainscreen cladding systems can last 30–50 years, with durable options like aluminium and stone offering even longer performance.

Yes, but for buildings over 18 metres, UK regulations require non-combustible (A1 or A2-rated) materials for fire safety compliance.

Many systems use recyclable materials and contribute to sustainable construction by improving energy efficiency and reducing heating and cooling costs.

Installation time depends on the system type, building size, and access, but prefabricated panel systems can speed up construction and reduce labour costs.

Would You Like To Discuss A Particular Project?

If you’re looking for a specialist curtain walling, facade, or cladding contractor to assist you with your upcoming project, ensuring on-time delivery and a smooth process from start to finish, our expert team are on hand and ready to assist you.