Glazing vs Cladding Fire Stops

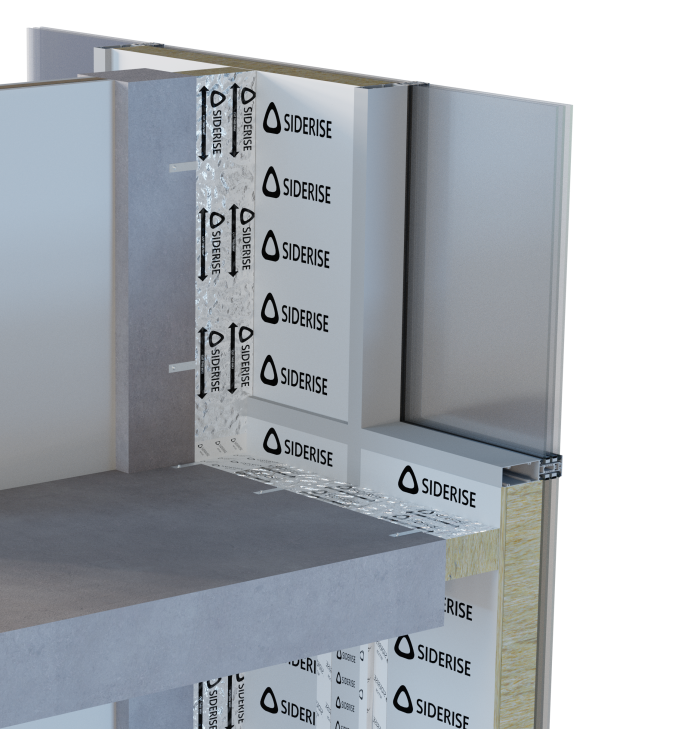

The fire stopping requirements vary depending on the façade system. Behind curtain walling or window systems, fire stops are typically installed at every compartment line — often slab edges or floor zones — and must be compressible yet retain their performance under movement and thermal load. These systems must interface tightly with mullions and framing to prevent the passage of flame or smoke.

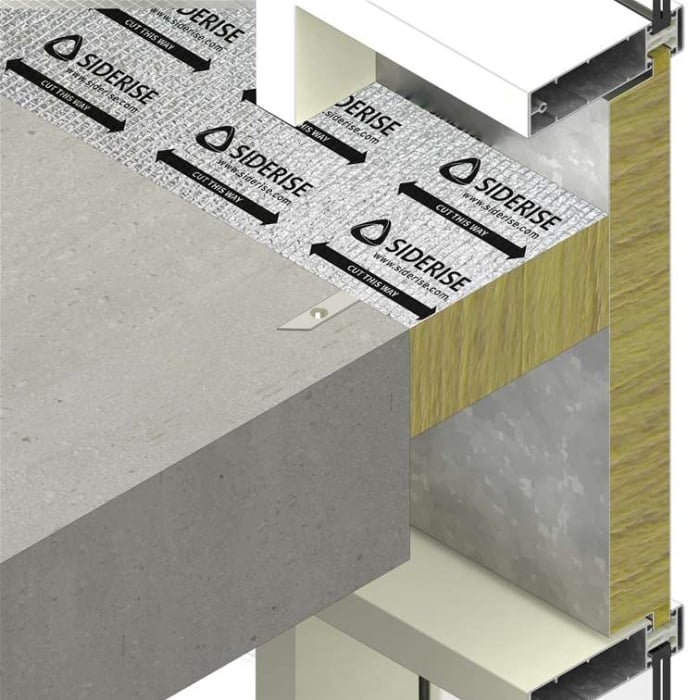

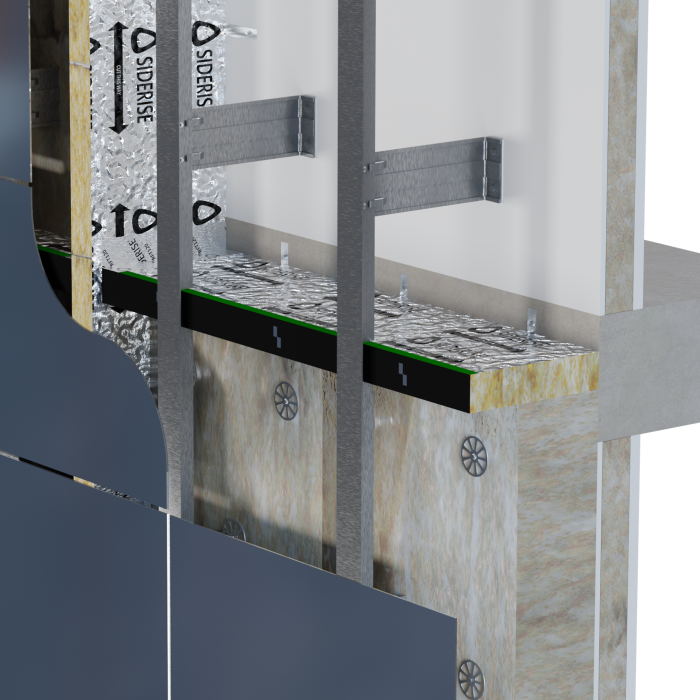

Behind rainscreen cladding, fire stopping is commonly installed horizontally (and in some cases vertically) between the inner wall and outer cladding at compartment lines, using open-state barriers that allow ventilation under normal conditions but expand to seal gaps in the event of fire. These must be installed with continuous contact to both the SFS or wall and cladding support system, with no gaps, sagging, or misalignment.