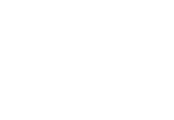

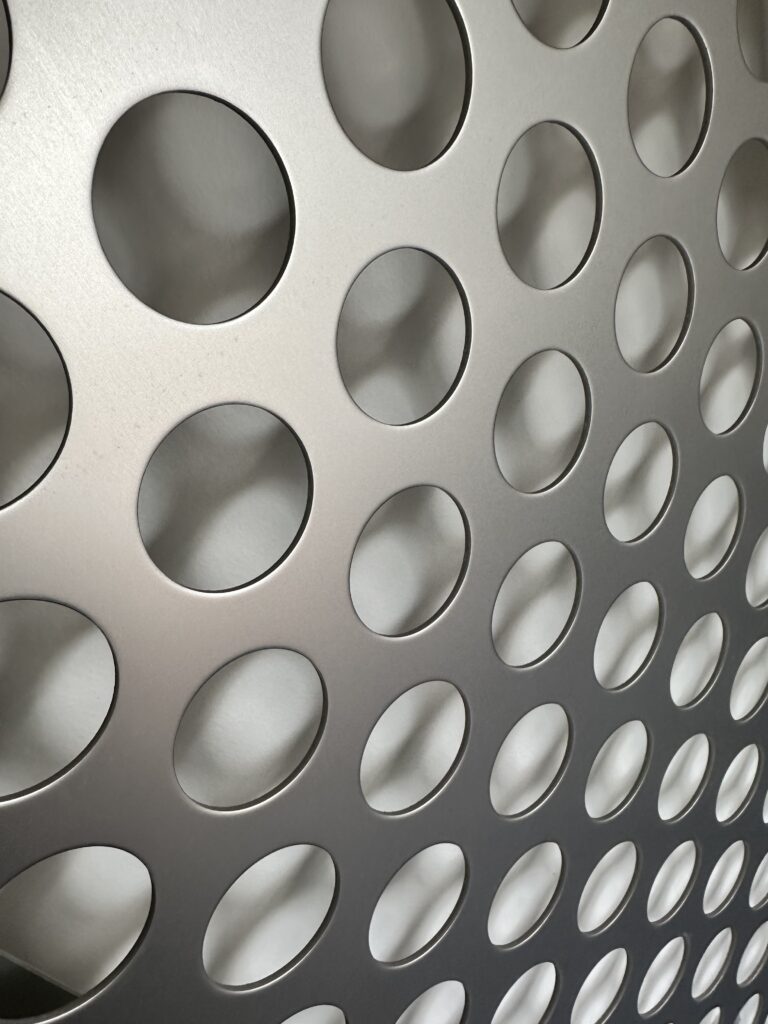

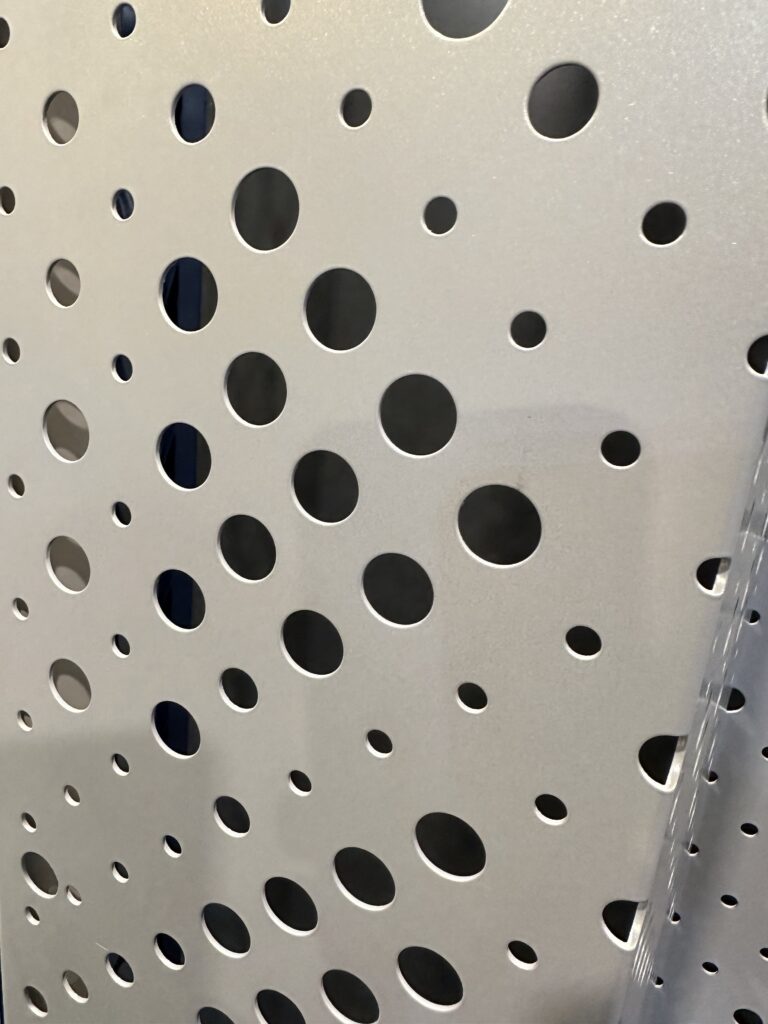

At Advanced Glass, we design, supply and install fall protection feature panels – a growing safety and design solution increasingly specified on modern façade projects.

These panels are mounted externally and positioned over internally opening windows to prevent the risk of falling, providing a discreet and elegant solution for buildings where window configurations would otherwise introduce a safety risk.