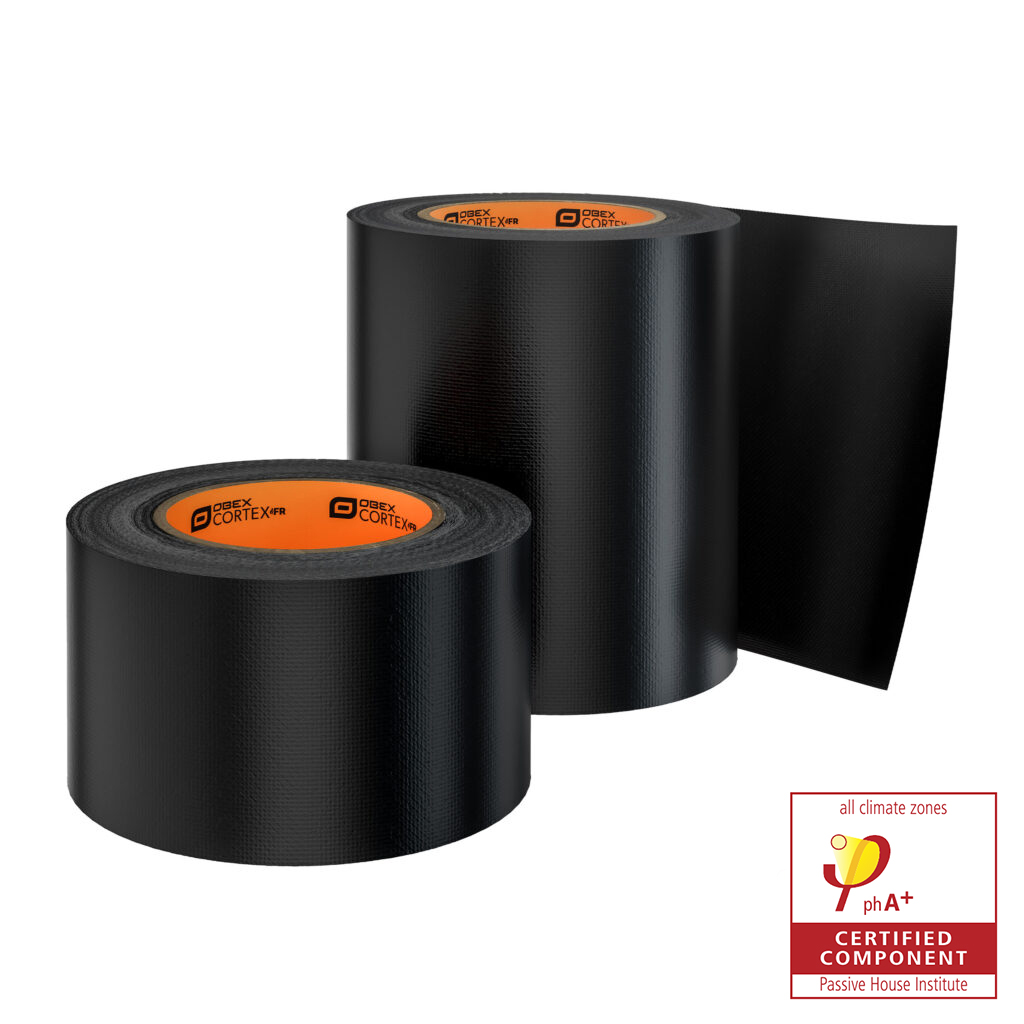

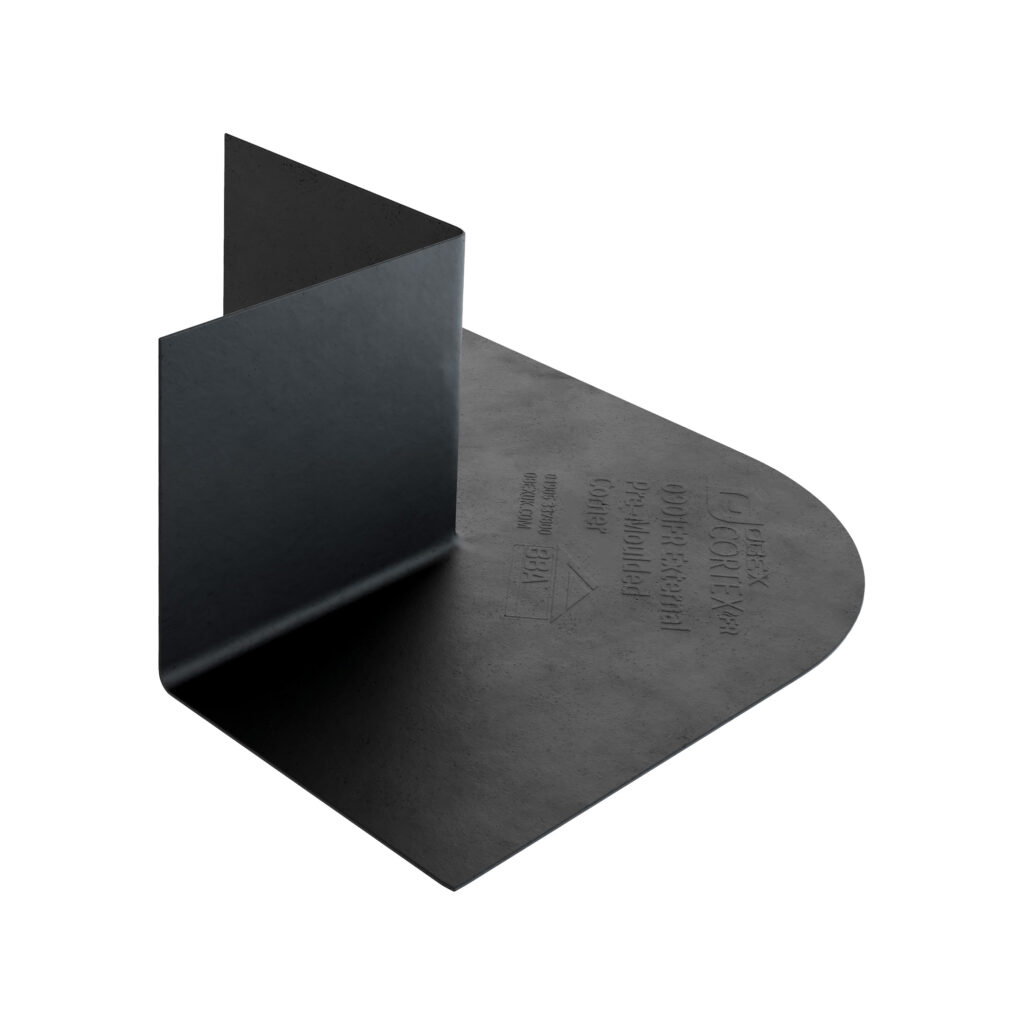

Why Use EPDM Membranes?

EPDM is valued for its excellent weather resistance, flexibility, and long lifespan. It remains effective under UV exposure, temperature variations, and mechanical stress, making it ideal for sealing around window frames, curtain wall junctions, coping details, and other challenging façade interfaces.

Fire Ratings & Compliance

EPDM membranes come in various fire performance grades, critical for compliance with the Building Safety Act and relevant standards such as BS EN 13501-1. Fire-rated EPDM membranes may be classified as Class B-s1, d0 or better, suitable for use on high-rise buildings where fire spread risks are tightly controlled.

Selecting the appropriate fire rating depends on the building’s height, occupancy type, and façade design, and is always integrated with the overall fire strategy coordinated by the design and fire engineering team.