Blast Rated Glazing

Advanced Glass: Blast Rated Glazing

Blast rated glazing systems are designed to provide protection against the effects of explosive forces — shielding occupants and assets from flying glass, pressure waves, and structural collapse. At Advanced Glass, we supply and install blast-resistant façades and glazed systems as part of an integrated building envelope solution, ensuring security is embedded in the very fabric of the structure.

Where Blast Rated Glazing is Required

These systems are typically specified for:

- Government and defence buildings

- Transport infrastructure (airports, rail, metro)

- Data centres and control rooms

- Commercial buildings in high-risk areas

- Laboratories and high-value asset facilities

- Energy and utility infrastructure

Key Features of Blast Resistant Glazing

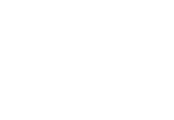

- Tested to international blast standards, including ISO 16933, GSA TS01-2003, and EN 13541

- Laminated glass with specially engineered interlayers to absorb shock waves and prevent fragmentation

- Framing systems designed to flex or absorb energy without detaching from the structure

- Compatible with curtain wall, punched window, or ribbon glazing formats

- Can be combined with ballistic, manual attack, or fire-rated performance for multi-threat protection

- Glazing thickness and system specification tailored to threat level and stand-off distance

Performance Tiers and Customisation

Blast rated glazing is not one-size-fits-all — we work closely with structural engineers and blast consultants to determine:

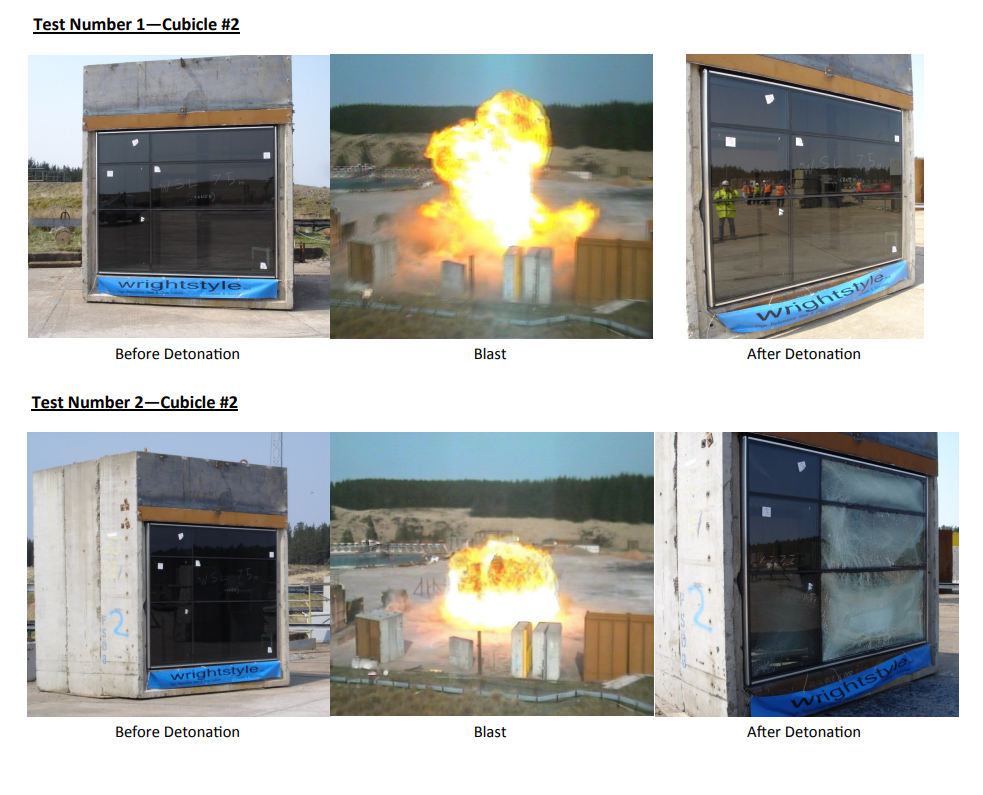

- Peak pressure and impulse duration (e.g., 100 kPa for light risk, 200+ kPa for high threat)

- Glass make-up: multi-layer laminated, annealed or heat-strengthened combinations

- Anchoring design: ensuring the frame and fixings resist deflection and pull-out forces

- Framing profiles: steel-reinforced or thermally broken aluminium systems

- Integration with building geometry: including recessed or inclined façades

Why Integrate Blast Glazing into the Envelope?

Advanced Glass specialises in delivering complete façade packages — and when blast-resistant elements are included at the early design stage, they can be structurally and visually integrated without compromise.

By coordinating with our in-house teams across SFS, cladding, curtain walling, and fire stopping, we help clients:

- Avoid system clashes and detailing issues

- Maintain thermal and acoustic performance

- Ensure correct sequencing and secure fixing

- Provide robust QA and installation records

- Streamline approval through Gateway 2 and 3

Protect people, assets, and operations with confidence.

Speak to Advanced Glass about designing and installing blast rated glazing systems — tailored to your specific security brief.

Frequently Asked Questions

Aluminium windows offer durability, low maintenance, excellent thermal efficiency, and modern aesthetics, making them ideal for commercial applications.

Yes, modern aluminium windows feature thermal break technology to improve insulation, achieving low U-values meeting Part L building regulations and often exceeding it.

Options include double or triple glazing, solar control glass, acoustic glass, laminated safety glass, and enhanced security glass, depending on performance needs.

Yes, commercial aluminium windows can be PAS 24 certified and meet Secured by Design standards with multi-point locking systems with reinforced frames.

When properly maintained, aluminium windows can last 30 – 40 years, due to their corrosion resistance and high-quality powder-coated finishes.

Yes, they are available in a wide range of RAL colours, anodised finishes, and different configurations, including casement, tilt-and-turn, and sliding options.

Aluminium windows are designed to withstand extreme weather conditions, with high wind load resistance and water-tightness ratings to ensure long-term performance.

Minimal maintenance is needed – just the occasional cleaning and lubrication of moving parts is required to help ensure smooth operation and longevity.

Yes, aluminium is up to 100% recyclable, and many modern aluminium window systems use recycled materials, supporting sustainable building practices.

Lead times vary depending on customisation and project size, but standard windows typically take 12 – 16 weeks for design, manufacturing and delivery.

Would You Like To Discuss A Particular Project?

If you’re looking for a specialist curtain walling, facade, or cladding contractor to assist you with your upcoming project, ensuring on-time delivery and a smooth process from start to finish, our expert team are on hand and ready to assist you.