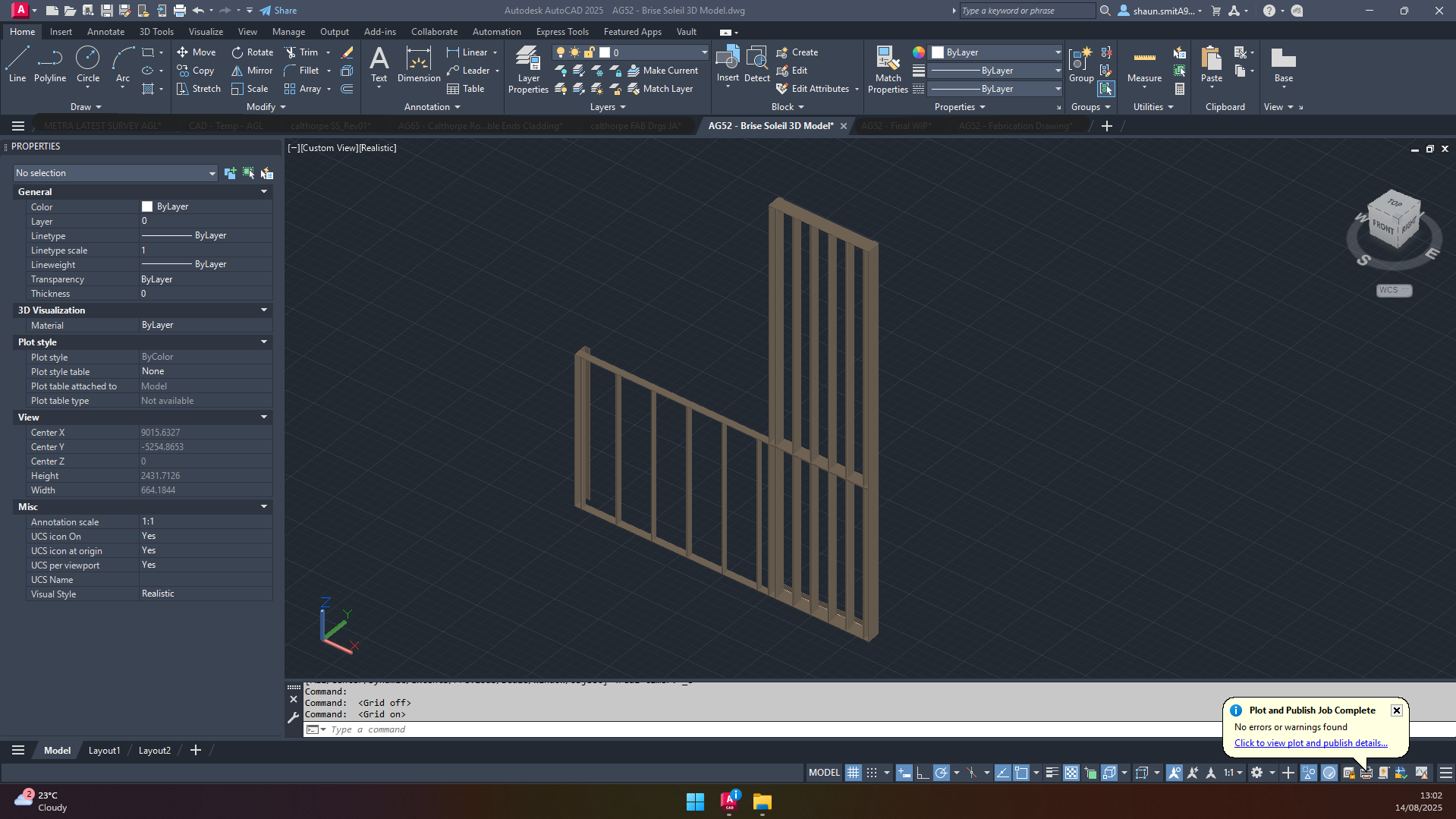

Barrier Louvres

Advanced Glass: Barrier Louvres

Barrier louvres are a high-performance solution that serve a dual purpose: delivering essential airflow to mechanical or plant areas while also providing certified fall protection in line with Building Regulations. As part of a complete envelope solution, barrier louvres are commonly specified on commercial, industrial, and high-rise residential projects where safety, ventilation, and aesthetics must be balanced.

What Are Barrier Louvres?

Barrier louvres are specialist louvre systems designed to meet both ventilation requirements and load-bearing safety standards, typically offering resistance to line loads as defined in BS EN 1991-1-1. They are especially suited for areas where traditional louvres may be insufficient — such as in front of openable windows, in rooftop plant enclosures, or in areas where personnel could come into contact with the louvre face.

Key Benefits

- Dual Functionality: Barrier louvres provide both natural or mechanical ventilation and certified protection against falls from height.

- Load Rated: Systems typically comply with line load ratings of 0.74 kN/m or 1.5 kN/m, making them suitable for low-risk and high-risk zones as outlined by UK Building Regulations.

- Non-combustible Construction: Manufactured using aluminium or galvanized steel with powder-coated or anodised finishes, barrier louvres can contribute to non-combustible façade design strategies for high-rise buildings.

- Customisable Appearance: Various blade profiles, colours, and finishes can be selected to match adjacent curtain walling, rainscreen cladding, or louvre systems, maintaining a coherent architectural expression.

Integration with the Façade

Barrier louvres can be fully integrated into façade systems — either as standalone panels, as part of plant screen enclosures, or directly into curtain walling. This allows for consistent interface detailing and simplified installation within the wider building envelope.

Mounting & Framing Options

While most barrier louvres are fixed to the primary structure or supporting steelwork, framing systems can be developed to enable coordination with curtain wall mullions or cladding rails. This approach improves alignment and helps reduce tolerance issues during install.

Applications

- High-rise residential buildings

- Rooftop plant screens

- Ventilated riser shafts

- Car parks and basement ventilation

- Data centres and commercial mechanical zones

Barrier Louvres as Part of a Complete Envelope

When installed as part of an integrated façade package — alongside curtain walling, cladding, fire stopping and SFS — barrier louvres can be seamlessly detailed to ensure there are no conflicts at interfaces. This avoids grey areas between subcontractors and ensures the fire strategy, fall protection, and airflow requirements are all addressed within a single coordinated solution.

Why Choose Advanced Glass?

As a specialist full façade contractor, Advanced Glass provides barrier louvre systems as part of a complete envelope solution. This means:

- Single-source responsibility for design, supply, and installation

- Elimination of coordination issues between multiple trades

- Full compliance with ventilation, fire, and fall protection requirements

- Documented QA sign-off, including test evidence and installation records

Need barrier louvres for your next project?

Get in touch with the team at Advanced Glass to explore fully integrated louvre solutions that deliver both safety and performance — without compromising on aesthetics.

Frequently Asked Questions

Aluminium windows offer durability, low maintenance, excellent thermal efficiency, and modern aesthetics, making them ideal for commercial applications.

Yes, modern aluminium windows feature thermal break technology to improve insulation, achieving low U-values meeting Part L building regulations and often exceeding it.

Options include double or triple glazing, solar control glass, acoustic glass, laminated safety glass, and enhanced security glass, depending on performance needs.

Yes, commercial aluminium windows can be PAS 24 certified and meet Secured by Design standards with multi-point locking systems with reinforced frames.

When properly maintained, aluminium windows can last 30 – 40 years, due to their corrosion resistance and high-quality powder-coated finishes.

Yes, they are available in a wide range of RAL colours, anodised finishes, and different configurations, including casement, tilt-and-turn, and sliding options.

Aluminium windows are designed to withstand extreme weather conditions, with high wind load resistance and water-tightness ratings to ensure long-term performance.

Minimal maintenance is needed – just the occasional cleaning and lubrication of moving parts is required to help ensure smooth operation and longevity.

Yes, aluminium is up to 100% recyclable, and many modern aluminium window systems use recycled materials, supporting sustainable building practices.

Lead times vary depending on customisation and project size, but standard windows typically take 12 – 16 weeks for design, manufacturing and delivery.

Would You Like To Discuss A Particular Project?

If you’re looking for a specialist curtain walling, facade, or cladding contractor to assist you with your upcoming project, ensuring on-time delivery and a smooth process from start to finish, our expert team are on hand and ready to assist you.